Products

Gate Valve

| Features | Outside Screw and yoke type, Bolted Bonnet Rising Spindle Design Used for Gas, Steam, Petrochemical & Oil supply upto -29" C to 425" C |

| Application | Petrochemical, Refinery, Steel Plants, Pulp & Paper Industries, Chemicals & Fartilise Industries, Sugar Plants & Process Industries |

| Design | API - 600 Bolted Bonnet, OS & YT, Rising Stem, Handwheel Operted |

| Testing Standard | API-598 |

| Type | Rising Valve |

| Size Range | 50mm to 1OOOmm |

| Rating | Class - 150 / Class - 300 / Class - 600 / Class - 900 / Class - 1500 Flanged- ANSIB 16.5 RF Class 150/PN-10/Customer Spec. |

| Ends | Flanged- ANSIB 16.5 RF Class 150/PN-10/Customer Spec. |

| Material of COnst Body | CS-ASTMA216Gr. WCB / CF8/ CF8M |

| Trim | 13% Cr.Steel/ AISI410 / 304 / 316/ Stalited overly |

| Working Pre./Temp | Hydro Test Pressure : Body Shell - 30 Kg/Cm(2) , Seat - 22 kg/em(2),Pneumatic 6.9 kg / Cm(2) |

| Temp. Range | -29 C to 425 |

| Operation | Handwheel Operated / Actuator Operated |

Globe Valve

| Features | Rising Spindle Bolted Bonnet Design Used for Gas, Steam, Petrochemical& Oil Supply upto -29 c to 425 C |

| Application | Petrochemical, Refinery, Steel Plants, Pulp & Paper Industries, Chemicals & Fartilise Industries, Sugar Plants & Process Industries |

| Design | BS1873 |

| Testing Standard | BS-6755 Part-1/API-598 |

| Type | Rising Valve |

| Size Range | 50mm to1OOOmm |

| Rating | Class 150/Class 300 / Class 600/ Class 900/ Class 1500 |

| Ends | Flnged ANSIB 16.5 RF Class 150/ PN-10 / CustomerSpee. |

| Material of COnst Body | CS-ASTM-A216, GrWCB/CF8/CF8M |

| Trim | 13% Cr.Steel/ AISI- 410,304,316 and Stalite Overly |

| Working Pressure | Hydro test pressure Body Shell 30kg/cm(2) , seat -22kg/cm(2) pneumatic 6.9 kgem(2) |

| Operation | Handwheel Operated/ Actuator Operated |

Check Valve

| Features | Single casting construction with double flanged swing type check valve with simple design and highly precision for hydrolie self flow control |

| Application | Petrol chemical refinery steel plant power plant, pulp & paper industries chemical & fertiliser industries, process industries and water works |

| Design Standard | BS 1868 Swing Type / API- 594 |

| Testing Standard | BS 6755 (Part-1) I API- 598 |

| Type | Non Return type flanged end / Swing type flanged end |

| Size Range | 50mm to 1OOOmm |

| Rating | Class 150 / Class 300 / Class 600/ Class 900/ Class 1500 |

| Ends | Flanged End Drilling B16.5 Class-150 & IS-1538 PN - 10 & PN-16 |

| Material of COnst Body | Cast SteelASTM A-216 Gr.WCB & CF8 / CF8M |

| HingPin/StopPin/Spring | Cast SteelASTM A-216 Gr.WCB & CF8 / CF8M |

| Body Seat Facing | SSAISI - 304I 410 I SS AISI - 304/410 |

| Working Pre./Temp | 13% Cr.Steel / AISI410I Stalite overly |

| Operation | 21kg/ em(2) Shell31kg/em(2) Temp.- 29 C 425 Self Operated |

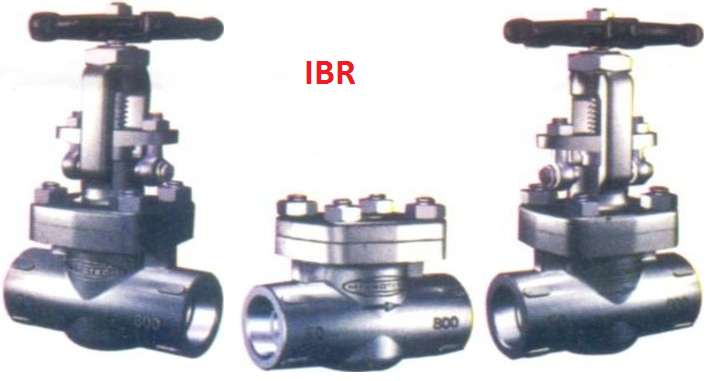

Forged Steel Valve

| Features | Compact design,Bolted Bonnet/ Cover, OS & Y type and rising stem (Gate & Globe), Spring loaded disc (Check) with renewable seat rings with IBR specifications |

| Application | Steam lines, Hot liquids line, Gas lines & Nuclear Plant |

| Design Standard | API - 602, BS : 5352 for Gate Valves BS : 5352 for Globe & Check Valves |

| Testing Standard | API - 598, BS : 6755 (Part 1) |

| Type | Reduced bore and Standard bore |

| Size Range | 8mm to 50mm |

| Rating | Class - 800 / Class 1500 |

| Ends | Screwed ends to BSP/BSPT/NPT Socket weld ends to ASME B16.11 Butt weld endsto ASME B16.25 (Flanged end also) |

| Material of Canst Body / Bonne / Cover | A105/F304/F316 |

| Wedge/Disc | CA15/CF8/CF8M |

| Seatring Gasket | SS41O/SS304/SS316 |

| Working Pre./Temp | 150Kg/Cm(2) - 200(2)- 250 C |

| Operation | Handwheel Operated (Standard) |

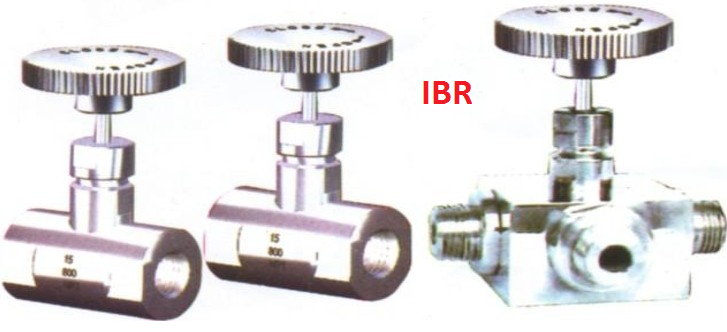

Needle Valve

| Features | Single Piece robust body construction, screwed-in bonnet with aesthetically & functionally designed Handwheel with powder coated painting |

| Application | Pnuematic system, Airlines, Steamlines, Gas & Oxygen, Acetylene industries |

| Design Standard | Manufacturers standard |

| Testing Standard | BS:6755 (Part-1) |

| Type | 2 way & 4 way Port Valve |

| Size Range | 3mm to 50mm |

| Rating | Class-800 / Class 1500 |

| Ends | Screwed Male / Female ends to BSP / BSPT / NPT Socketweld ends to ASME B16.11 |

| Materialof Const. Body / Bonnet | SS410/ SS304/SS316 |

| Needle | SS41O/SS304/SS316 |

| Packing/Seal | PTFE/PA 12 |

| Working Pre./Temp | 150kg/Cm(2) - 180 - 425 C |

| Operation | Handwheel Operated (Standard) |

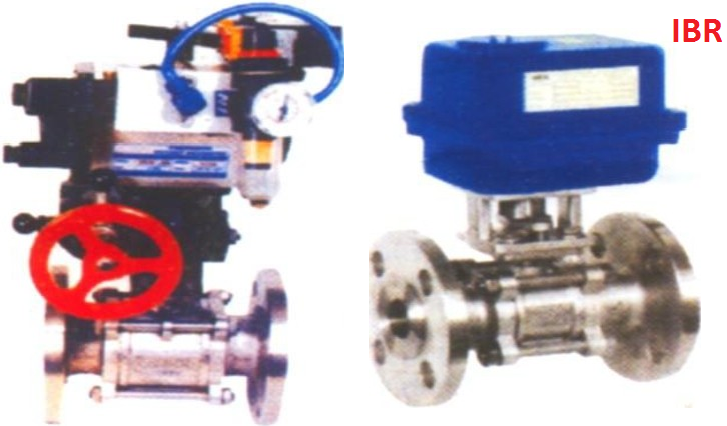

Ball Valve

| Features | Single Piece,Two Piece & 3 Way L-Port & L-Port floating type fire safe quarter turn Valve for On-Off Service & Anti Static Design |

| Application | Petrol-chemical, Fertilizer Oil & Gas, Sugar, Pulp & Paper, SteelIndustries and Power Plants |

| Design Standard | BS :5351, BS ENISO :17292-2004 |

| Testing Standard | BS : 6755 (Part-1) |

| Type | Full Bore / Reduce Bore |

| Size Range | 15mm to 250mm |

| Rating | Class 150 and Class 300 |

| Ends | Flanged Ends to ANSIB :16.5 Raised face/Flat face |

| Material of Const | Body/Side Piece : A216-Gr. WCB/CF8/CF8M |

| Trim | SS410/SS 304/SS316 |

| Working Pre./Temp | 15Kg/Cm - 40kg/em•180•C - 200•C |

| Seat and Seals | PTFE!GFT/RPTFE/MatalSeat for high Temperature |

| Operation | On-Off Type Modulating Controlled |

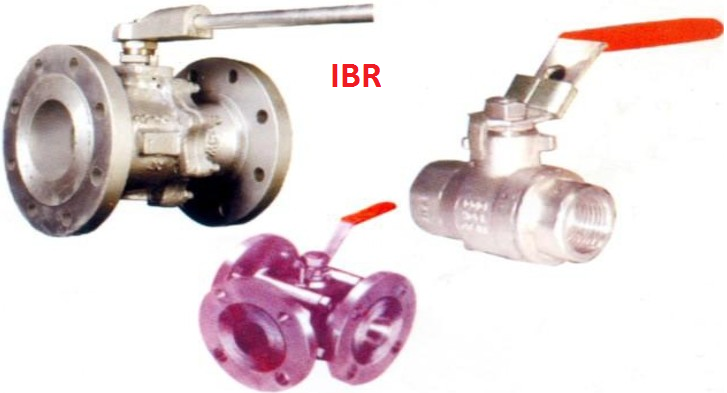

Flanged End Ball Valve

| Features | Single Piece, Two Piece & 3 way L-Port & T-Port floating type fire safe Quar ter turn Valve for On-Off Service Anti-Static Design |

| Application | Petro-chemical, Fertilizer, Oil & Gas, Sugar, Pulp & Paper Industries and Power plants |

| Design Standard | BS:5351,BSENISO:17292-2004 |

| Testing Standard | BS:6755 (Part-1) |

| Type | Full Bore / Reduced Bore |

| Size Range | DN 15 TO DN300 |

| Rating | Class 150 and Class 300 |

| Ends | Flanged ends to ANSIB:16.5 Raised face/Flat face |

| Material of Canst Body / Bonne / Cover | Body/Side Piece:A216-Gr.WCB/CF8/CF8M |

| Trim | SS41O/SS3041SS316 |

| Working Pre./Temp | 15Kg/Cm(2) - 40Kg/Cm(2)180(2) - 200 C |

| Seat and Seals | PTFE/GFT/RPTFE/MetalSeat for hightemperature |

| Operation | Lever Operated upto DN1OOFB Gear operated DN150FB and above |

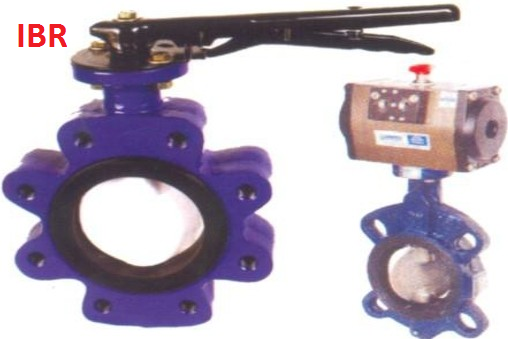

Butterfly Valve

| Features | Lugged / Solid waffer type design with 90 turn valve for On Off services |

| Application | Waterworks, Sugar Plants & Pulp & Paper Industries |

| Design Standard | AWWA-C-504, BS-5155, API-609 |

| Type | Lugged waffertype/Solid waffertype |

| Size Range | 40mm to 300mm |

| Rating | Class 150 / P N -10 |

| Ends | Lugged / Solid |

| Material of Canst Body / Bonne / Cover | Cl,SGI, WCB,CA-15,CF8,CF 8M |

| Trims | SS-410,SS-304, SS-316 & EN-19 |

| Seats & Seals | Neoprene, Nitrile, EPDM< Hypolone, Butyle, Silcon, Nordel, PTFE etc. |

| Disc Bond | Ebonite/Rubber (Center Disc) |

| Working Pre./Temp | 24Kg/Cm(2) / 200with Synthetic Rubber |

| Operation | Hand lever operated upto 150mm. Above 150mm - 300mm Gear Operated |

Sluice Gate Valve

| Features | Inside & Outside Screw and yoke type,Bolted Bonnet,Rising & Non Rising spindle design,user for water supply upto 80 deg C |

| Application | Water works, Sugar plants, Pulp & Paper Industries, Chemical, & Fertiliser Industries,ProcessIndustries |

| Design Standard | IS : 14846 (IS-780) and BS-1414 |

| Testing Standard | BS :6755 (Part-1) & API-598 |

| Type | Rising & Non Rising Valve |

| Size Range | 5Omm to 1200 mm |

| Rating | PN 1.0 and PN 1.6 and Class-150 |

| Ends | Flanged ends ANSI-B16.5 FE-RF to 'D' table,PN-10 IS-1538 & to suit customer requirements |

| Materialof Canst Body/Bonnet/Wedge | Cast IronIS:210 Gr.FG200/ASTM-A-216 GrWCB |

| Stem/Seatring Seals | Brass/SS 41OI SS 304/SS 316 |

| Working Pre./Temp | For CI-SLV Valve Hydro seat-1OkgI cm2 shell15kg/cm2 Temp 40 deg-80 deg C. For CS GTV - working pressure # 150 seat 22kg/cm2, shell 30kg/cm2 Air 6.9kg/cm2 Back seat 22kg/cm2 Temp - 50 deg - 180 deg C. |

| Operation | Handwheel Operated (Standard) & Actuator available on customer demand |